- What is the Industrial Internet of Things (IIoT)?

- IoT vs IIoT: what’s the difference?

- How does IIoT work?

- Examples of IIoT applications

- Benefits of IIoT for businesses

- Challenges of deploying IIoT devices

- The future of IIoT

- IIoT connectivity

What is the Industrial Internet of Things (IIoT)?

The Industrial Internet of Things (IIoT), also known as the industrial internet, refers to using interconnected smart sensors and other devices to collect and share data to enhance industrial processes. By connecting devices that process data in real time, IIoT can improve operational efficiency, productivity and safety.

IIoT is increasingly used in sectors like manufacturing, energy management, logistics and transport. For example, IIoT-enabled sensors and devices on production lines can help ensure quality control, optimise energy usage and enable predictive maintenance – spotting issues before equipment fails.

Together with emerging technologies like AI, big data analytics and robotics, the Internet of Things is one of the main drivers of the Fourth Industrial Revolution.

IoT vs IIoT: what’s the difference?

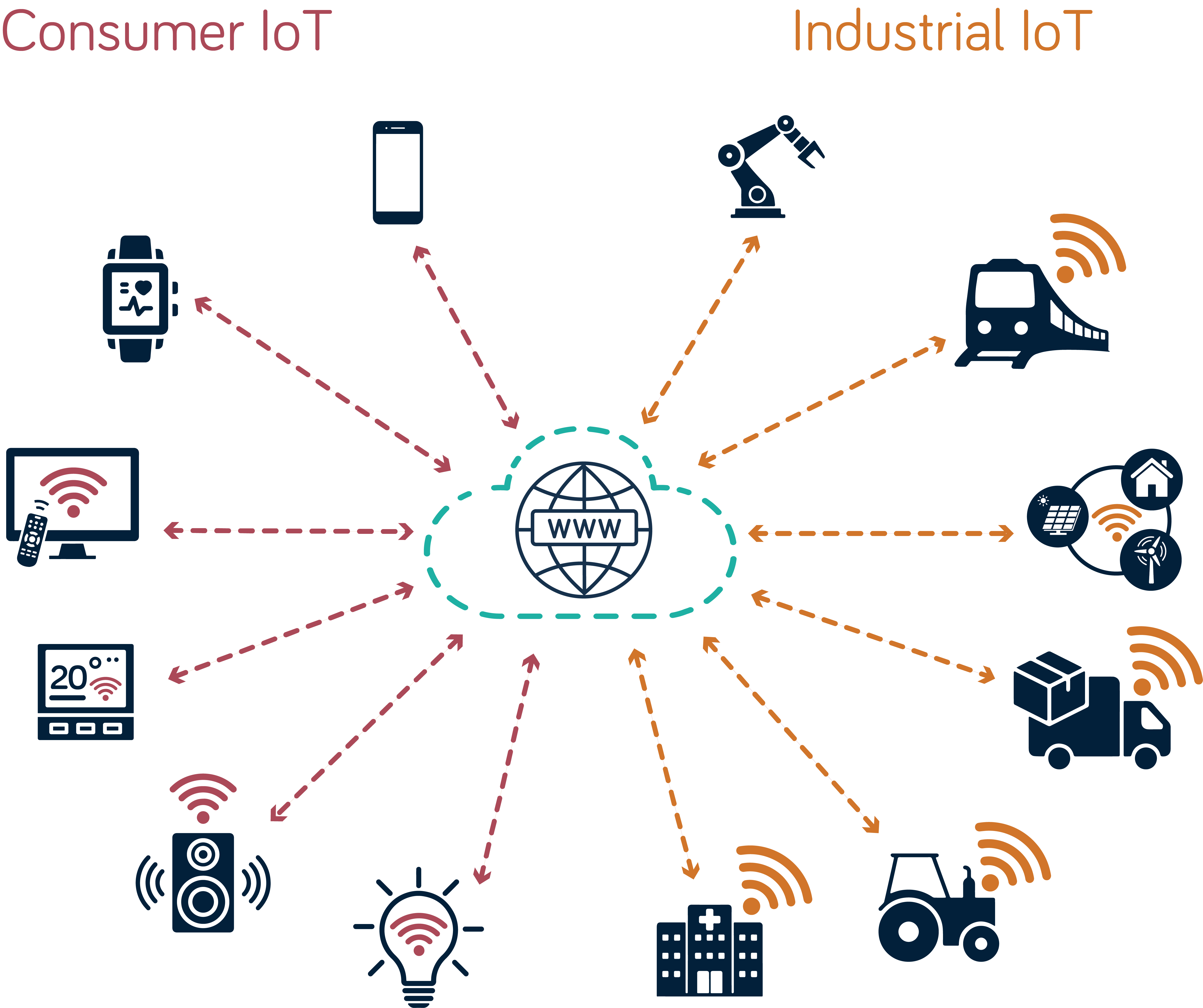

The Internet of Things (IoT) is a general term that refers to connecting devices to the internet to remotely control them, from smart home gadgets to city infrastructure. Consumer IoT applications, like smart TVs, smart thermostats and wearable fitness trackers, focus on convenience and enhancing user experience.

A subset of IoT, Industrial IoT (IIoT) refers to connecting devices in large-scale industrial environments like factories and warehouses. Since IIoT failures can lead to costly downtime or safety hazards, IIoT focuses on ensuring high reliability and low latency for precise real-time control.

IoT vs. IIoT

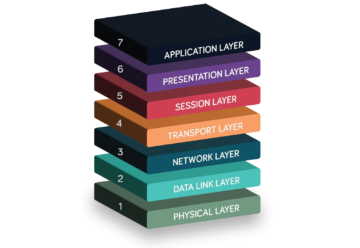

How does the Industrial Internet of Things work?

IIoT works by connecting machines, sensors and other devices to the internet to collect, monitor and analyse data in real time. Here’s how it works in more detail.

IIoT-enabled devices

Sensors or other devices built into industrial machinery collect data such as temperature, pressure, speed and vibration. For example, a vibration sensor in an industrial motor may collect data on the level of vibration in the device.

Connectivity

The sensors and devices are connected using wired or wireless network protocols like Wi-Fi, Bluetooth, Ethernet or 5G. They send data to a central server or cloud-based IIoT platform for real-time analysis.

Edge computing

Some data may be aggregated and initially processed locally using edge networking and edge computing. This reduces latency and bandwidth usage by enabling real-time analysis without sending all the data to the central server or cloud.

Data analytics

Once in the central server or cloud, data is aggregated and analysed using big data analytics, AI or machine learning to identify and act on patterns in the data. For example, certain vibration levels in an industrial motor can be used to predict a breakdown before it occurs.

Insights and automation

The processed data may be visualised in dashboards, allowing operators to monitor critical metrics and take action to optimise processes. Similarly, IIoT systems may directly control machines based on insights from real-time data analysis, optimising efficiency and automating routine tasks.

By harnessing real-time data analysis and automation, IIoT systems can significantly enhance the efficiency, resilience and scalability of industrial processes.

Examples of IIoT applications

From production lines and supply chains to energy management and healthcare, IIoT is used for various applications in a wide range of industries. Here are some common examples.